The pathway to successful design

Being able to identify high stress locations in a part and using modelling to predict how the fibres will orientate has allowed the design of parts with thinner walls to enable functionality, reduce weight and to improve overall performance primarily through:

- Tailoring the fibre orientation in the direction of critical stresses.

- Tailoring fibre content to the strength and stiffness required.

- Tailoring melt flow in the mould to achieve desired fibre orientation and weld lines are moved to areas of low stress.

- Employing low shear moulding processes with generously sized runners and gate.

- And utilising FEA and MFA analysis to design and test in the initial stages before building the moulds.

- Duromer will work with you to take your idea through to a viable product.

- Our engineers are passionate.

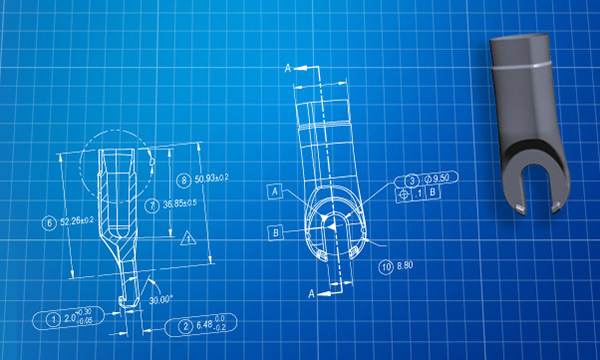

- A design philosophy that proves the requirements in simulation before going to tooling.

- Our field experiences inspire us – transferring technology across industries.

- Our composites are true 3D structures (just like metal castings).